Press Force for Dry Granulation

The Influence of Press Force and Gap on Ribbon and Granule Properties in Roller Compaction

Press force and the gap between press rollers are the two main drivers in dry granulation. The applied press force is called the specific press roller force (specified in kN/cm) while the minimum distance between the press rollers is the gap [mm]. Force and gap are immensely affecting the ribbon density in roller compaction. Therefore, both are main factors to be considered in the configuration of the roller press machine. Press force as well as the gap have an influence on the ribbon and the granule properties which causes different effects on the resulting tablets. What these effects look like and how to handle them? You will find the answers below.Configuration of the Roller Press Machine: Getting the Intended Results with the Press Roller

Ultimately, the configuration of the press roller depends on the intent. The question to ask here is: What density should the granules have? Basically, a larger specific press force results in ribbons with higher density. Depending on the material’s properties, the resulting granules are often coarser. However, these granules generate mostly softer tablets. You see: The press force has a significant effect on the granules’ texture and can cause softer tablets whereas the impact of the gap is the opposite. Regarding the impact of the gap, a larger gap emerges in less densified ribbons. The results are smaller granules and stronger tablets. The extent of this influence is smaller in respect to gap than to force and depends on the compacted material itself. An overview:- A larger press roller force results in ribbons with higher density (softer tablets)

- A larger gab results in less densified ribbons (stronger tablets)

Roller Compactor: What Are the Different Functional Units For?

To get intended results, the roller press machine has further parameters to be set. All parameters can be assigned to the functional units. A roller compactor consists of three of those units:- the dosing unit

- the densification unit

- the milling unit

Ribbon Density: The Role of Press Force and Gap

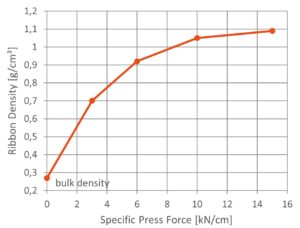

Ribbon density is the main determining factor for granule properties. To realize the major impact of press force and gap, the ribbon density as well as the granule properties must be considered. Beside the ribbon density, especially the material itself which is roller pressed is influencing the granule properties.Impact of the Specific Press Force on Ribbon Density

On the chart you can see an example of the influence of the specific press force on the ribbon density. The starting point is set at 0kN/cm. Following the graph, a larger press force results in ribbons with higher density. Thereby, you see an increase of density which is non-linear and which finally flattens towards higher densities. Why? Because more and more force is required to reach further densification of the material.Impact of the Gap on Ribbon Density

Not only the specific press force has an impact on the ribbon density. The gap as well affects the density of ribbons. Larger gaps in ribbons can be reached with lower density by having a constant press force. The chart on the right shows an example of the ribbon density as a function of press force for two different gaps. In this example, you see that at an equal press force with a 4mm gap reaches lower densities than the one with a 2mm gap. An explanation for the huge effect of the gap on ribbon density can be the thin layer model by Peter et al.[1] All in all, the layer model describes that a larger gap results in a larger nip area. Consequently, the intent is to distribute the press force over a larger area to reach a less densified powder. Ultimately, the extent of this reduction depends on the densification properties of the material. So keep in mind: The extend of the reduction cannot be generalized, because each material is unique.Re-compatibility: How to Generate Strong Tablets

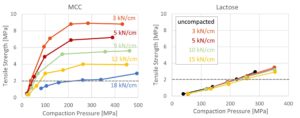

To generate strong tablets, the influence of the ribbon density on the granule properties is determining. Especially their re-compatibility (the ability of the granules to generate strong tablets) is of importance. In the case that the material is densified once into the ribbon, we speak of a re-compaction or second densification in terms of the re-densification into a tablet. On the right you see the re-compatibility for two different substances depending on different press forces. Obviously, the impact of the press force is strongly substance specific. On the other hand, microcrystalline cellulose (MCC) shows a strong decrease of achievable tablet strength. Clearly, lactose shows barely noticeable impact. Since the bonding sites of the particles are meant to produce the ribbon, most substances, which are roller compacted, show a certain loss in binding capacity. In general, 2 MPa is the target value for tablets and both substances can achieve this target. Figure 3: Impact of the specific press force on the re-compactability of two different substancesThere Is a Third Player to Press Force and Gap

Example of the influence of press force on the particle size distribution of granulates MCC in roller compaction